Understanding the Art of Welding: How to Prevent Undercut Welding Issues for Flawless Fabrication Outcomes

Efficiency and accuracy are extremely important in the world of welding, where also the tiniest imperfection can jeopardize the architectural integrity of a fabricated item. One typical obstacle that welders face is damaging, a problem that can deteriorate a weld joint and lead to pricey rework. By understanding the root triggers of undercut welding and applying effective strategies to prevent it, welders can raise their craft to brand-new degrees of quality (Preventing weld undercut). In the pursuit of remarkable manufacture results, mastering the art of welding to prevent undercut concerns is not just a skill however a need for those pursuing perfection in their work.

Comprehending Undercut Welding

To stop undercut welding, welders must make certain appropriate welding criteria, such as adjusting the existing, voltage, traveling rate, and preserving the correct electrode angle. By understanding the causes of undercut welding and applying preventive steps, welders can achieve top quality, structurally audio welds.

Root Causes Of Undercut in Welding

Comprehending the variables that contribute to damage in welding is essential for welders to produce high-grade, structurally sound welds. Insufficient welding existing or incorrect welding rate can also contribute to undercut. Recognizing these reasons and carrying out proper welding methods can aid prevent undercutting problems, making sure solid and durable welds.

Methods to avoid Undercutting

To alleviate the danger of undercutting in welding, welders can use critical welding strategies aimed at enhancing the quality and integrity of the weld joints. Additionally, making use of the proper welding strategy for the specific joint setup, such as weave or stringer beads, can contribute to reducing damaging.

Employing back-step welding methods and controlling the weld bead account can likewise help distribute warm equally and lessen the risk of undercut. Regular assessment of the weld joint during and after welding, as well as carrying out quality assurance procedures, can assist in finding and resolving damaging issues promptly.

Value of Proper Welding Parameters

Choosing and maintaining suitable welding specifications is important for achieving effective welds with marginal problems. Welding specifications refer to variables such as voltage, present, travel speed, electrode angle, and protecting gas flow rate that straight impact the welding process. These parameters must be thoroughly adjusted based upon the kind of product being bonded, its density, and the welding strategy used.

Correct welding criteria ensure the ideal amount of warmth is used to melt the base steels and filler product consistently. If the parameters are set too high, it can cause extreme warmth input, creating burn-through, distortion, or spatter. On the site link other hand, if the parameters are also reduced, insufficient combination, lack of penetration, or undercutting may happen.

Quality Control in Welding Operations

Final Thought

In conclusion, grasping the art of welding needs a complete understanding of undercut welding, its reasons, and methods to stop it. By guaranteeing correct this content welding specifications and executing quality control methods, flawless manufacture results can be achieved. It is necessary for welders to regularly pursue quality in their welding operations to stay clear of undercut problems and produce top notch welds.

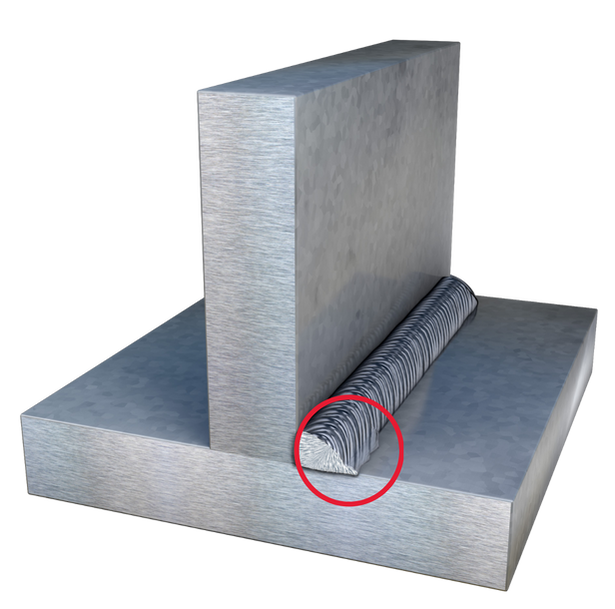

Undercut welding, a common issue in welding processes, takes place when the weld metal does not correctly load the groove and leaves a groove or depression along the bonded joint.To prevent undercut welding, welders need to guarantee correct welding parameters, such as changing the existing, voltage, travel rate, and maintaining the right electrode angle. Poor welding wrong or current welding speed can additionally contribute to undercut.To minimize the risk of undercutting in welding, welders can utilize strategic welding get more methods intended at boosting the quality and stability of the weld joints.In verdict, understanding the art of welding requires a detailed understanding of undercut welding, its causes, and techniques to avoid it.

Comments on “Professional Strategies for Preventing Weld Undercut Efficiently”